The role of robotics in manufacturing has been rapidly increasing in recent years, with more and more companies turning to automation to enhance productivity and safety in their operations. From small and medium-sized enterprises to large multinational corporations, robotics technology has become an indispensable tool for mexico manufacturing looking to gain a competitive edge in their respective markets.

The use of robotics in manufacturing offers several benefits, including increased efficiency, improved quality, reduced costs, and enhanced safety. Robotics companies Australia that support and enhance human potential.Let’s take a closer look at how robotics technology is revolutionizing the manufacturing industry.

Contents

Enhancing Productivity

One of the primary benefits of robotics in manufacturing is the significant improvement in productivity that automation provides. Robots can work continuously without the need for breaks, which allows for 24/7 production cycles that increase output and efficiency. Automation also reduces the likelihood of human error, which can lead to costly mistakes and wasted resources. By automating repetitive and time-consuming tasks, such as assembly line operations, manufacturers can significantly increase their production rates and reduce their lead times.

Improved Quality

Robots are highly accurate and precise, making them an ideal tool for quality control and inspection tasks. Automation can detect and correct defects in products more efficiently and effectively than manual inspections, leading to higher quality products and a reduction in waste. In addition, robotics technology allows for real-time monitoring of production processes, which helps manufacturers identify and correct issues before they lead to costly mistakes or product recalls.

Reduced Costs

Robotic automation can also help reduce manufacturing costs in several ways. By automating repetitive tasks, manufacturers can eliminate the need for manual labor, which can reduce labor costs and improve overall production efficiency. Automation also reduces the likelihood of errors and defects, which can lead to costly product recalls, waste, and rework. Additionally, robotics technology allows for better inventory management, reducing the need for excess inventory and the associated costs of storage and management.

Enhanced Safety

Robots are particularly useful in environments that are dangerous or hazardous for humans. For example, robots can perform tasks in environments with high temperatures, toxic chemicals, or radiation that would be unsafe for human workers. Automation can also reduce the risk of accidents and injuries in manufacturing environments by taking over repetitive or strenuous tasks that can lead to worker fatigue and injury.

Types of Robotics in Manufacturing

There are several types of robotics used in manufacturing, each with its unique features and applications. The most common types of robotics used in manufacturing include:

- Articulated Robots

Articulated robots are the most common type of robot used in manufacturing. They have a series of joints that allow them to move in a wide range of motions, making them ideal for applications such as welding, painting, and assembly.

- SCARA Robots

SCARA robots have a horizontal arm that can move in a circular motion and a vertical arm that can move up and down. This makes them ideal for applications such as pick-and-place operations and material handling.

- Cartesian Robots

Cartesian robots, also known as gantry robots, have three linear axes of motion that allow them to move in a straight line along each axis. This makes them ideal for applications such as material handling and assembly.

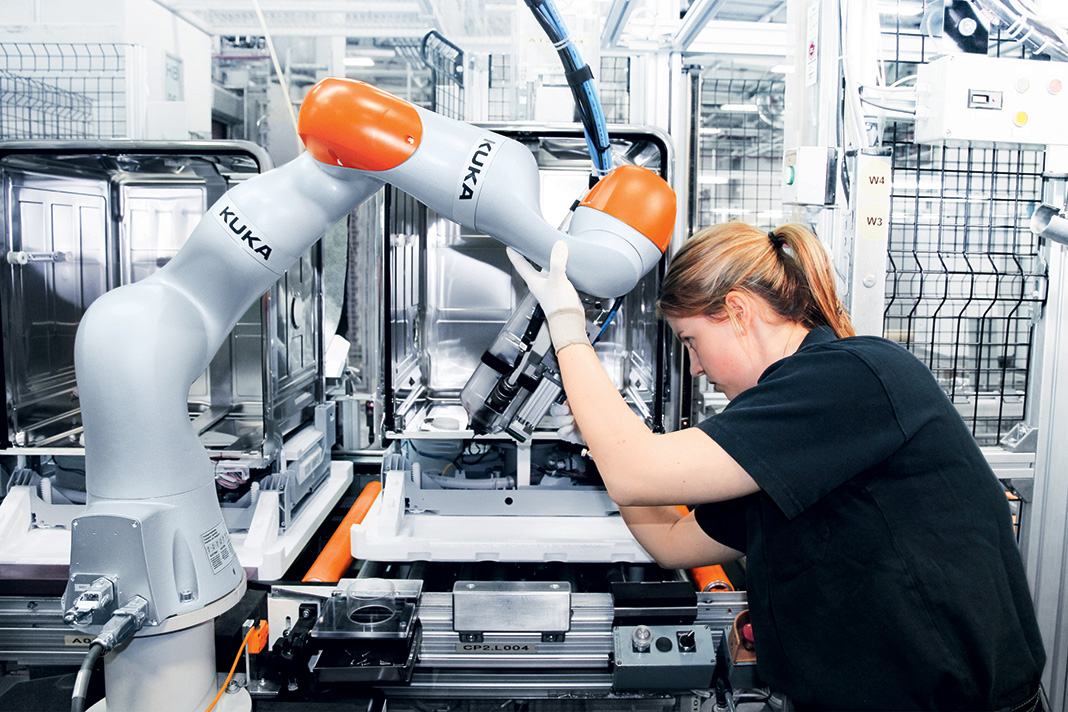

- Collaborative Robots

Collaborative robots, also known as cobots, are designed to work alongside human workers. They are equipped with sensors that allow them to detect the presence of humans and adjust their movements to avoid collisions and reduce the risk of injury.

- Mobile Robots

Mobile robots are designed to move autonomously through a manufacturing environment. They are equipped with sensors that allow them to navigate around obstacles and can perform a variety of tasks, including material handling and inspection.

The Future of Robotics in Manufacturing

As technology continues to evolve, the role of robotics in manufacturing is likely to continue to expand. Advancements in artificial intelligence and machine learning are expected to lead to

more sophisticated and intelligent robots that can adapt to changing manufacturing environments and perform more complex tasks. The integration of robotics technology with other advanced technologies such as 3D printing, augmented reality, and the Internet of Things (IoT) is also expected to bring about significant improvements in manufacturing efficiency and productivity.

In addition, the growing demand for customization and personalization in manufacturing is expected to drive the development of robots that can quickly and efficiently produce small batch sizes of customized products. This will enable manufacturers to better meet the needs and preferences of individual consumers while still maintaining high levels of efficiency and productivity.

Conclusion

The use of robotics in manufacturing has revolutionized the industry by enhancing productivity and safety, improving quality, and reducing costs. Robots have become an indispensable tool for manufacturers looking to gain a competitive edge in their respective markets. With the continued advancements in robotics technology and its integration with other advanced technologies, the future of manufacturing looks promising and exciting. The manufacturing industry will continue to evolve, and robotics will play a critical role in shaping the future of manufacturing.